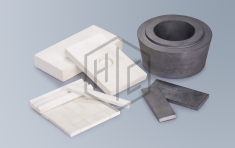

Lining for protection against wear and corrosion

Lining with technical ceramics is used to protect various equipment against mechanical and corrosive wear.

It is characterized by:

- high strength and durability;

- resistance to high temperatures;

- corrosion resistance;

- low specific weight.

The main types of equipment that use lining:

- crushing and shredding equipment (centrifugal-impact crushers, vortex, rotary, jet, abrasive, coal mills, etc.);

- equipment for the classification and enrichment of ore (hydrocyclones, etc.);

- pumping equipment, centrifuges;

- cyclones and calcinators of cement plants, concrete mixers;

- capacitive equipment;

- lining of conveyor chute, pipelines, feeders, conveyors, pulp conditioning units, drums of magnetic separators, screws, etc.

Installation of lining is carried out with the help of adhesive joints, cementing, mechanical fastening or welding. Possible materials: aluminum oxide, zirconium dioxide, silicon carbide, as well as other ceramic materials for special requests.

HTTC Co. delivers lining, including the individual geometry of equipment, advises on installation issues, selection of installation facilities.

Service life of such ceramic lining is usually 5-15 times higher than life of lining by chromium-nickel alloys, stone casting, polyurethane and rubber.

HTTC Co. serially produces lining plates for X-ray luminescent separators for the diamond mining industry and sand caps for hydrocyclones.

Please feel free to contact our specialists on any related issue.