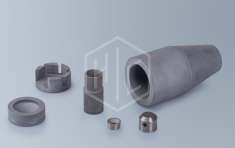

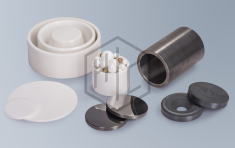

Wear-resistant products for the mining industry, crushing, separation

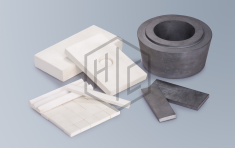

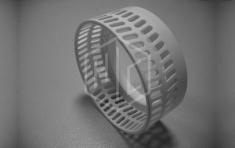

Wear-resistant ceramic and cemented carbid materials are used in various equipment where protection from prolonged exposure to abrasive particles is required.

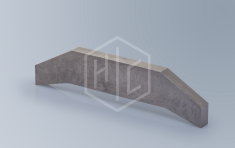

Wear of parts as a result of moving and grinding large volumes of solid particles or suspensions can be unexpectedly large, even if the particles are not considered too hard. The resulting wear is a combination of erosion due to collision with particles at large angles and abrasive wear at small angles of collision with particles where plastic wear mechanisms predominate. The wear mechanism depends on a number of variables: the size of the particles, the “sharpness” of their shape, mass, speed, hardness, applied load and angle of abrasive incidence. When selecting wear-resistant products, other factors should be taken into account: operating temperatures and the risk of corrosion.

At the same time, the products should maintain their operational properties for a maximum time.

Accordingly, the following requirements are imposed on wear-resistant products for the mining industry, crushing, separation:

- hardness;

- wear resistance;

- mechanical strength;

- corrosion resistance;

- low or high density;

- high degree of reliability and economy in operation.

Please feel free to contact our specialists on any related issue.

Информация о вёрстке

Данная страница создана с использованием новейших технологий - flex-вёрстка, без использования сторонних CSS-фреймоворков (Bootstrap и т.д). Это делает страницу гибкой, легкой и отзывчивой.

- Кроссбраузерность - страница корректно отображается во всех современных браузерах. Протестировано в Mozilla, Chrome, IE11, Opera.

- Адаптивность - страница корректно отображается на различных размерах экрана, на различных устройстах

- Минимум кода, высокая скорость загрузки страниц - отказ от сторонних библиотек позволил значительно ускорить время загрузки страницы

- Семантичность - использование новых стандартов HTML5, CSS3 делает страницу более структурированной. Поисковики любят такие страницы.

- Валидная верстка (верстка без ошибок) - верстка, выполненная в соответствии со стандартами W3C. Проверить свою HTML-страницу на корректность вы можете с помощью специального валидатора W3C (Кроме этого блока, который затем удалится.)

Developed by VusalStudio. vusaldev@gmail.com