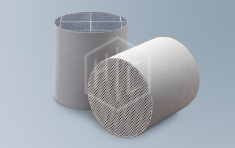

Ceramic catalysts carriers

A catalyst is a substance that accelerates the course of a chemical reaction without undergoing an irreversible change. Catalysts are important not only for the chemical industry, but also for solving environmental problems.

A catalyst is a substance that accelerates the course of a chemical reaction without undergoing an irreversible change. Catalysts are important not only for the chemical industry, but also for solving environmental problems.

Ceramic structures with a high specific surface are used as carriers for catalysts. The high specific surface should be preserved after long-term use, as well as geometry and mechanical properties, which implies the carrier’s resistance to thermal and mechanical stresses and to chemical destruction.

Ceramic catalysts carriers are usually used:

- for purification of gasoline and diesel automobile engines exhaust;

- for chemical and petroleum refining processes;

- for cleaning emissions of power plants and other industrial enterprises.

The main requirements for catalyst carriers include a large surface area, heat resistance, porosity, chemical inertness, mechanical strength.

Ceramic and metal carriers compete with each other: ceramics are often more stable and more economical, and therefore dominate in most sectors. Metal is sometimes preferable because of greater mechanical strength and the ability to manufacture catalysts of a certain geometry using wire, foil or thin-wall honeycomb structures.

Please feel free to contact our specialists on any related issue.