Materials

The level of modern equipment complexity requires the use of modern high-tech materials. Technical ceramics and cemented carbides apply in case of where none of traditional materials can withstand the demands.

Technical ceramics and cemented carbides have found their application in extreme operating conditions due to a set of unique properties, such as:

- resistance to wear;

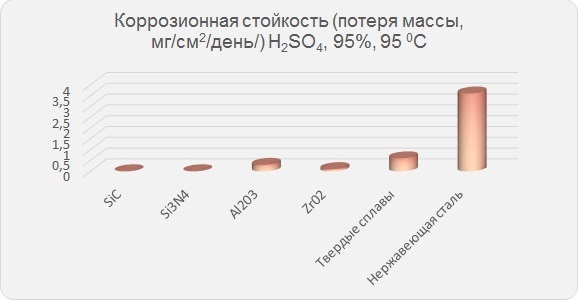

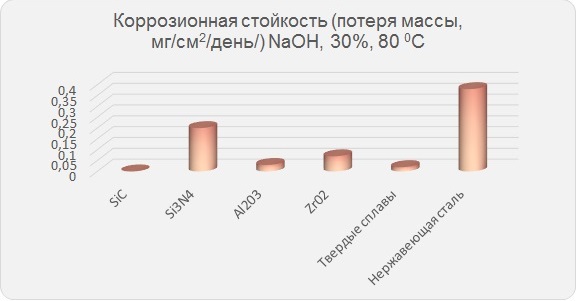

- resistance to corrosion;

- low density;

- excellent tribological properties;

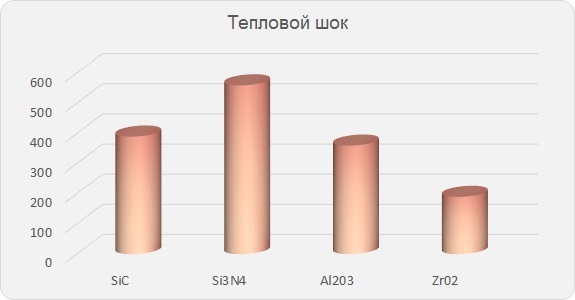

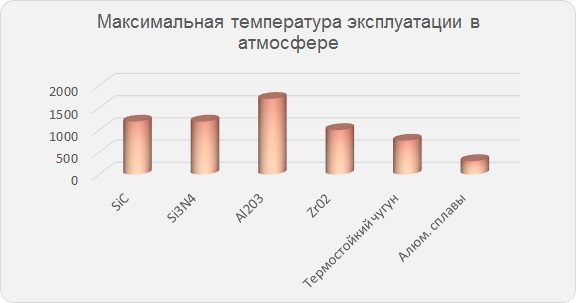

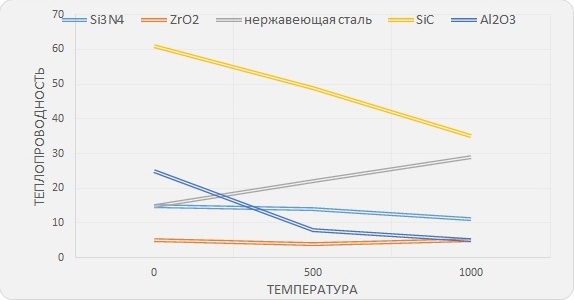

- resistance to high and low temperatures, heat shock;

- low coefficient of thermal expansion;

- high thermal conductivity;

- dielectric or semiconductor properties.

The introduction into production products from ceramic and cemented carbide materials isn’t a trivial process. The simple replacement of traditionally used materials with ceramics without taking into account features of its production technology and the unique properties of each kind of ceramics and cemented carbide won’t give the expected result in the majority of cases. Only joint work of equipment designers, operational services and specialists in the field of technical ceramics and cemented carbide will provide the most cost-effective and efficient solution to acute production problems.

Our specialists are ready, in close cooperation with customers, to carry out the whole cycle of innovative works from development of basic technical solutions and designs to supply and introduction products from ceramics and cemented carbide into production processes.