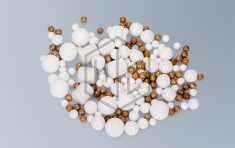

Grinding bodies

Grinding bodies of various shapes and compositions are used in ball mills, bead mills, agitators, attritors for fine or ultra-fine grinding, as well as for grinding and polishing.

Grinding bodies of various shapes and compositions are used in ball mills, bead mills, agitators, attritors for fine or ultra-fine grinding, as well as for grinding and polishing.

Main applications:

- mining industry;

- production of technical ceramics (piezo ceramics, insulators, electronic components, etc.);

- production of sanitary ceramics;

- production of paints, pigments, coatings, glazes, inks;

- production of quartz sand;

- production of fine calcium carbonate (GCC);

- production of cement;

- production of fertilizers;

- food, cosmetics, pharmaceuticals.

Basic materials: Zirconia (ZrO2), alumina (Al2O3), silicon carbide (SiC), silicon nitride (Si3N4), hard alloy.

Below are the most common execution options. For more information, please contact our specialists.

Grinding balls of alumina (90-92%Al2O3, 98-99,7%Al2O3)

Beads (grinding microspheres) of alumina (90-92%Al2O3, 98-99.7%Al2O3)

Suitable for wet and dry grinding. Not recommended for high speed aggregates.

Main advantages:

- excellent wear resistance;

- good chemical stability, no grinding;

- low cost (compared to other ceramic materials).

Grinding balls of zirconia (partially stabilized with Y2O3 or CeO2)

Beads (grinding microspheres) from zirconium dioxide (partially stabilized with Y2O3)

It is widely used in high-speed vertical and horizontal mills.

Recommended for use with high-speed micro-fine wet grinding.

Main advantages:

- excellent strength;

- excellent wear resistance;

- high density;

- close size distribution and smooth surface;

- optimum results when processing high-viscosity materials.

Please feel free to contact our specialists on any related issue.