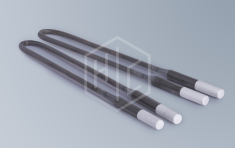

Disilicide-molybdenum heaters

Disilicide-molybdenum heaters (MoSi2) are designed for both continuous and periodic operation in a neutral medium, vacuum and oxidizing environment up to 1800°С.

Disilicide-molybdenum heaters (MoSi2) are designed for both continuous and periodic operation in a neutral medium, vacuum and oxidizing environment up to 1800°С.

One of the unique advantages of a disilicide-molybdenum heater is the formation a protective film of silicon dioxide on the surface, which prevents further oxidation of the heater material.

Also, disilicide-molybdenum heaters have the following advantages:

- increase in resistance with increasing temperature, which provides faster heating;

- constant resistance during the whole service life, which makes it easier to replace old heaters with new ones;

- high load at high temperatures, which allows heating to a higher temperature on a small volume of the furnace.

Main applications:

- sintering of ferrites, technical ceramics and refractories;

- glass industry;

- growing crystals etc.

Please feel free to contact our specialists on any related issue.