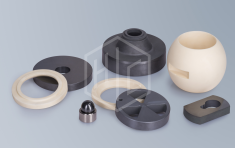

Ceramic elements of shutoff and control valves

The process equipment involved in the pumping and transport systems for liquid and gaseous media contains a significant number of shut-off and control valves. Elements of valves and fittings directly overlapping the flow are subject to a destructive effect of the flow, in the case of abrasive particles, corrosive media, high temperatures and cavitation leads to a drastic reduction in the resource and the need for frequent replacement of reinforcing units. The use of high-strength ceramic materials, resistant to corrosion and wear, allows increasing the life of equipment many times.

The process equipment involved in the pumping and transport systems for liquid and gaseous media contains a significant number of shut-off and control valves. Elements of valves and fittings directly overlapping the flow are subject to a destructive effect of the flow, in the case of abrasive particles, corrosive media, high temperatures and cavitation leads to a drastic reduction in the resource and the need for frequent replacement of reinforcing units. The use of high-strength ceramic materials, resistant to corrosion and wear, allows increasing the life of equipment many times.

The scope of ceramic elements is quite wide:

- ball valves;

- throttle pairs;

- disc valve;

- fitting;

- gate valves;

- valve pairs (ball-saddle).

Experience in the use of ceramic elements shows a significant reduction in the effect of “grasping” the elements of construction, reducing the opening/closing forces of the reinforcement, increasing the temperature range of operation and the overall increase in reliability and longevity of the unit. Silicon carbide, aluminum oxide, cemented carbide, zirconium dioxide, silicon nitride are used for the production of shut-off and control valves.

Please feel free to contact our specialists on any related issue.