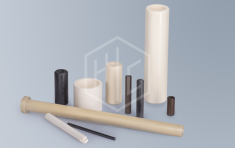

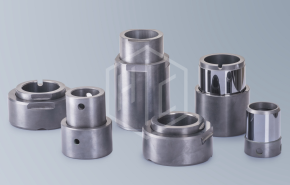

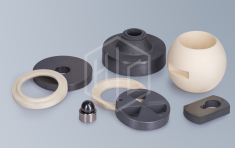

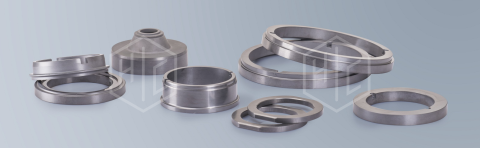

Wear-resistant parts of pumps, compressors, turbines, fittings

At present, wear-resistant parts made of ceramic materials, cemented and graphite are an integral part of pumps, compressors, turbines and pipeline fittings.

Main applications:

- installations of the electric centrifugal pumps;

- pipeline accessories;

- rod deep pum;

- pumps to maintain pattern pressur;

- rotary-plate vacuum pumps;

- sealed pum;

- plunger pumps;

- slurry and mud pumps;

- main line and supporting pum;

- power and feed pumps;

- various compressors and turbines.

Advantage of ceramic materials:

- excellent wear resistance;

- excellent corrosion resistance;

- excellent coefficient of friction;

- high thermal conductivity (heat removal from the friction zone, reduction of the temperature gradient and, accordingly, temperature stresses and deformations);

- high modulus of elasticity (resistance to force deformations);

- low temperature coefficient of linear expansion;

- manufacturability (the possibility of providing a high quality surface treatment).

Materials:

- aluminum oxide (corundum, alundum);

- silicon carbide;

- zirconia;

- cemented carbide;

- graphite and impregnated graphite.

Please feel free to contact our specialists on any related issue.