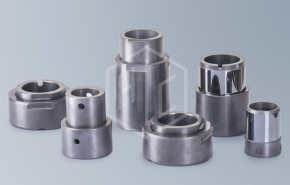

Sliding bearings

Sliding bearings for installations of the electric centrifugal pumps.

Sliding bearings for installations of the electric centrifugal pumps.

At present, high-strength ceramic materials and cemented carbide have firmly entered the design of electric centrifugal pumps for lifting formation fluid. Depending on the electric centrifugal pumps dimensions and the layout features, sliding bearings (radial and axial) made of reactive silicon carbide and cemented carbide are used, in rare cases from partially stabilized zirconia. From the point of view of sliding bearings design in installations of electric centrifugal pumps, relatively simple geometric shapes predominate, including individual structural elements (for example, grooves for passing a pumped medium acting as a cooling fluid). In the majority of cases, bearings installed in pump sections are operated in a mixed mode of friction (hydrodynamic and boundary), as a result the outstanding properties of ceramic materials, primarily high hardness, have a significant influence on the reliability of the unit. The characteristics of the bearings make it possible to use them with a significant amount of solid mechanical impurities in the pumped medium, ensuring the necessary service life of the entire unit.

Sealed pump bearings.

According to manufacturers of sealed pumps, their reliability is mainly determined by the reliability of the bearing units. The specificity of the use of hermetic pumps in chemical and petrochemical plants for corrosive media pumping requires the use of corrosion-resistant materials in pump assemblies. Taking into account the simultaneous impact of loads from friction and the weakening of the structure of the material under the influence of an aggressive environment in the bearings, such properties of ceramic materials as hardness, corrosion resistance, low coefficient of friction come to the fore in reliability. The use of ceramic materials such as reactive silicon carbide, sintered silicon carbide, composite materials based on silicon carbide and carbon in the design of sliding bearings of sealed pumps has become a standard solution for the world’s leading manufacturers. Options in the structural design of bearing assemblies are small, and differ, mostly by individual structural elements associated with the peculiarities of fixing of ceramic elements contraction and the organization of lubricant circulation.

There are 2 main types of sealed pumps:

- with a shielded engine;

- with magnetic coupling.

For hermetic pumps, ceramic housing, ceramic shafts and other parts are also manufactured according to customer’s drawings.

Please feel free to contact our specialists on any related issue.