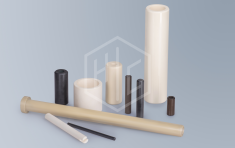

Ceramics in plunger (piston) pairs.

Unlike friction pairs of sliding bearings, where in most cases the rotation of one body relative to the other occurs, in aggregates using plungers or pistons reciprocating motion is realized. The friction pairs, depending on the design of the unit, can vary both for materials and for the arrangement of the solid and elastic element (sealing). In the constructions, there are solid liners on which the elastic element slides. This element located on the piston (for example, drilling, mud, slurry pumps). And there are solid plungers that slide over the pump packing in the friction couple liner (for example – metering pumps, diaphragm pumps, etc.). Depending on the specific implementation of the friction pair, the use of ceramics as a solid element material significantly increases the characteristics and durability of the unit, which leads to a significant economic effect throughout the life cycle of the equipment. For mud pumps, the overhaul period grows to 4000 hours or more, which is 5-10 times greater when using steel plugs of plungers. There are the following factors that ensure this effect:

Unlike friction pairs of sliding bearings, where in most cases the rotation of one body relative to the other occurs, in aggregates using plungers or pistons reciprocating motion is realized. The friction pairs, depending on the design of the unit, can vary both for materials and for the arrangement of the solid and elastic element (sealing). In the constructions, there are solid liners on which the elastic element slides. This element located on the piston (for example, drilling, mud, slurry pumps). And there are solid plungers that slide over the pump packing in the friction couple liner (for example – metering pumps, diaphragm pumps, etc.). Depending on the specific implementation of the friction pair, the use of ceramics as a solid element material significantly increases the characteristics and durability of the unit, which leads to a significant economic effect throughout the life cycle of the equipment. For mud pumps, the overhaul period grows to 4000 hours or more, which is 5-10 times greater when using steel plugs of plungers. There are the following factors that ensure this effect:

- reduced coefficient of friction in a pair;

- increased temperature range of operation;

- the possibility of obtaining a high quality treatment of friction surface (dimensional accuracy and low roughness);

- high corrosion resistance.

Most often, aluminum oxide, zirconia and silicon nitride are used as plunger pair materials.

Please feel free to contact our specialists on any related issue.